Research Areas

- Computational Mechanics- Multiscale Mechanics of Materials and Structures

- Mechanical Metamaterials and Hierarchical Structures

- Composite Materials and Structures

- Seismic Engineering

- Simulation and Characterization of the Dynamic Response of Materials and Structures

- Structural Optimization

Active Research Projects

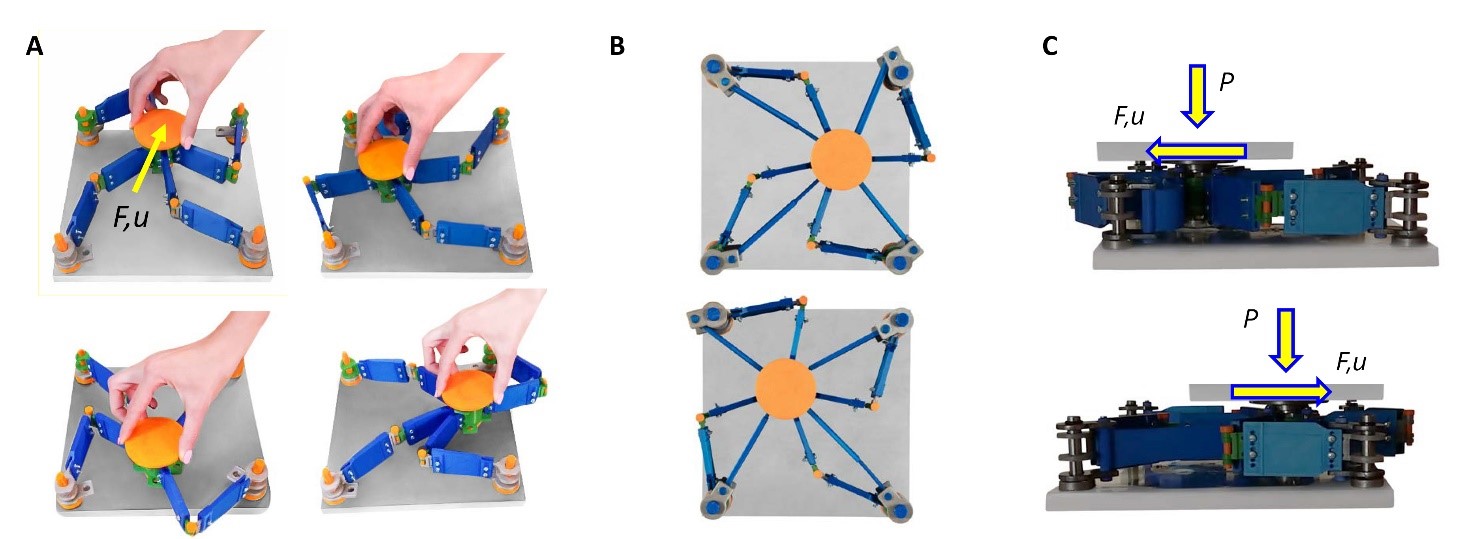

Biomimetic seismic metaisolators(Extracted from Fraternali, F., Singh, N., Amendola, A., Benzoni, G., Milton, G.W.. The 3D print job that keeps quake damage at bay. NATURE 600 (7887), 10, doi: http://dx.doi.org/10.1038/d41586-021-03506-2)

“A device inspired by human arms and legs could help to reduce how much a building shakes during an earthquake. Seismic isolators are placed between a structure and its foundations to protect against shaking ground. They are already widely used, but are generally expensive and difficult to install. Fernando Fraternali at the University of Salerno in Italy and his colleagues took a different approach. Their prototype consists of four ‘limbs’ with joints that connect a central post to the four corners of a plate. The post rests on a slippery circular disk called a slider and is connected to the ends of the limbs by stretchable ‘tendons’ made of thermoplastic polyurethane. When the researchers moved the post from its central position, friction and the restorative nature of the tendons dampened its motion. The device, which can be built using 3D-printed components and other common tools and metallic parts, could make it easier and cheaper to protect structures from earthquakes. The tendons’ size and composition can be changed, which could make them more tunable than the rubber bearings used in many conventional seismic isolators, the scientists say.”

Physical models and experimental validation. A Motion animation of a demonstrative version of prototype #1 equipped with fully 3D-printed unit cell parts, which can be moved by hand. B Demonstrative version of prototype \#2 equipped with telescopic tendons (see Movie S3 for a motion video-clip). C Prototype #2 with stretchable tendons and metallic posts under testing.

(Extracted from Fraternali, F., Singh, N., Amendola, A., Benzoni, G., Milton, G.W.. A biomimetic sliding–stretching approach to seismic isolation. NONLINEAR DYNAMICS, 106(4), 3147-3159, 2021, doi: https://doi.org/10.1007/s11071-021-06980-5)

Motion animation of a demonstrative prototype with 3D-printed parts and telescopic tendons.

Featured video of the deformation of the tendons of a prototype under testing (P = 25 kN).

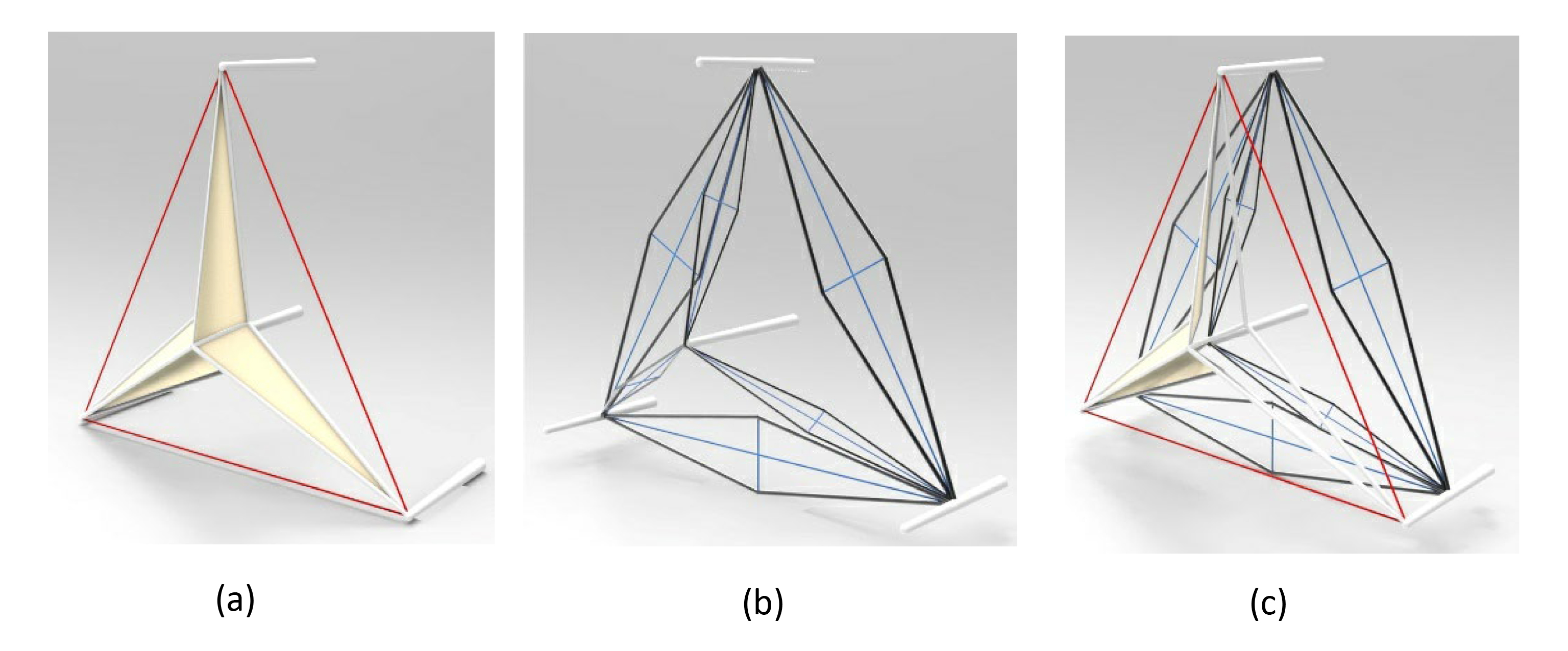

Origami solar facades with tensegrity architecture

(Extracted from Miranda, R., Babilio, E., Singh, N., Santos, F., Fraternali, F. Mechanics of smart origami sunscreens with mechanical energy harvesting ability, MECHANICS RESEARCH COMMUNICATIONS, 105, 103503, 2020. doi: 10.1016/j.mechrescom.2020.103503)

This research project deals with a reformulation of the design of the origami sunscreens with tensegrity architecture recently proposed to form the dynamic envelops of the Al Bahar Towers in Abu-Dhabi (Armstrong, A., et al, The Arup Journal 2, 60–73, 2013). A new design of the tensegrity Al Bahar screens (TABS) studied in TABS_REFERENCE has been carried out (Sect. 2), in order to develop novel dynamic sunscreens with wind and actuation energy harvesting ability, which are referred to as WTABS (WTABS_REFERENCE). The TABS façade is composed of ‘origami’ (umbrella shaped) eyes, whose unit cell (or basic module) consists of a tensegrity structure formed by 12 bars and 3 perimeter strings. The activation motion of each module is controlled by stretching and relaxing the perimeter strings, which leads to suitably tune the geometric stiffness of the structure. In the WTABS system, three-dimensional D-bar elements are added to the TABS modules, with the aim of profiting from the displacement amplification properties of such structures. It is shown that the WTABS can act as lightweight and cost-effective shading systems, with peculiar energy harvesting abilities.

Illustration of the WTABS model: (a) elementary TABS module; (b) D-bar tensegrity elements with mechanical energy harvesting abilities; (c) overall WTABS module (extracted from WTABS_REFERENCE).

Simulation of the actuation motion of the WTABS module.

Design, modeling, additive manufacturing and testing of lattice metamaterials

This area of research originates by studies I have conducted in recent years on the computational design, maunfacturing and experimentation of a variety of periodic lattices and mechanical metamaterials, and foam-like structures at macro, micro, and nanoscales, such as, e.g., granular systems (GRANULAR 1, GRANULAR 2, GRANULAR 3, GRANULAR 4), carbon nanotube (CNT) foams and multilayered CNT structures (CNT 1, CNT 2, CNT 3, CNT 4, CNT 5), and tensegrity materials and structures (TENSEGRITY 1, TENSEGRITY 2, TENSEGRITY 3, TENSEGRITY 4, TENSEGRITY 5, TENSEGRITY 6, TENSEGRITY 7). I have carried out such studies at Unisa, Caltech and UCSD. My research interests are focused on periodic arrays of masses and lattice units featuring a variety of special mechanical behaviors, which include: extreme values of mass/stiffness/strength parameters, frequency bandgaps, topologically protected edge modes, control of sound focusing and propagation, wave steering and directional behaviors. My research is aimed at deepening the fundamental understanding of lattice mechanics, and its application to the design, modeling, and manufacturing of innovative multiscale materials and structures. Lattice structures are employed at different scales, to form cellular solids; devices; fibers and fabrics; and building-scale structures. An additional goal of this research consists of applying mechanical metamaterials in engineering fields where current knowledge of such systems is only partial, like, e.g., civil engineering and sustainable construction (ITALY-USA project)).

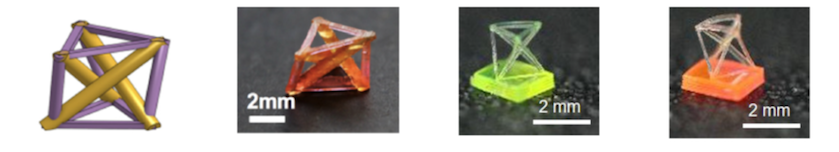

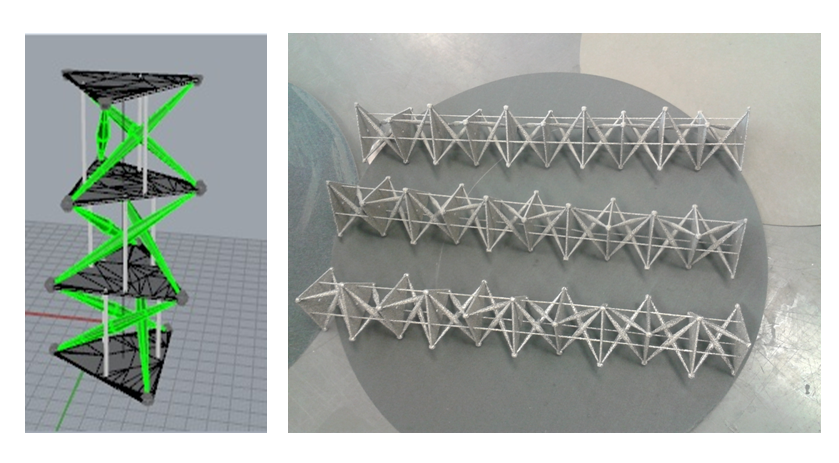

A modeling research line of this research studies the effects of internal and external prestress on nonlinear lattice mechanics, with the aim of designing arbitrary lattice behaviors. Material-scale applications of multiscale lattices deal with novel dynamic devices and hierarchical composite materials. A structure-scale application exploits lattices with morphing abilities to design adaptable envelopes for energy efficient buildings The present research line leads to the computational design, modeling, and fabrication of new materials and structures, using innovative concepts. Use is made of 3D printing technologies such as multiscale additive manufacturing of tensegrity structures through electron beam melting, laser lithography and/or projection micro-stereolithography. Particularly interesting is the use of 3D micro-fabrication technologies for the manufacturing of miniaturized tensegrity structures. (in collaboration with Chiara Daraio at the ETH, link; Vitali Nesterenko at the UCSD, link; Nicholas Boechler at the University of Washington, link; and Howon Lee at the Rutgers University, link).

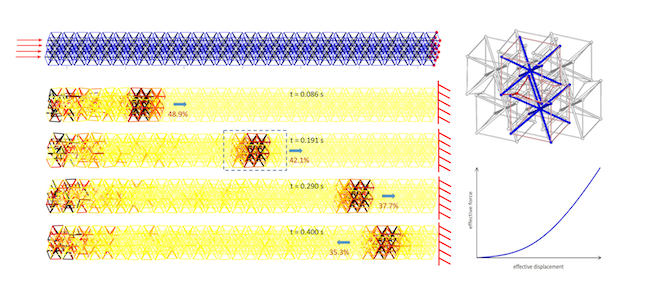

Propagation of compact compression waves in 2d and 3D tensegrity beams with stiffening type response

(Animation of the compact wave dynamics of 2d and 3d tensegrity beams, paper)

| Softening response of a thick tensegrity prism. |

| Propagation of a rarefaction wave in a precompressed tensegrity lattice featuring elastic softenining. |

Microscale tensegrity prisms manufactured through projection micro-stereolithography

Computer modeling (left) and additive manufacturing via electron beam melting (right) of physical models of tensegrity lattices in titanium alloy Ti6Al4V (in collaboration with the

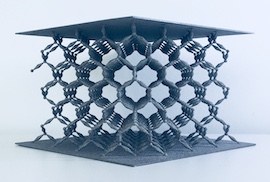

Use of confined lattice structures for the design of novel seismic metamaterials

The nascent field of mechanical and acoustic metamaterials, defined as engineered lattice materials that feature unconventional behaviors mainly derived by the geometry of their microstructure, rather than from their chemical composition, is growing rapidly and attracting increasing attention from many research areas - including acoustics, aerospace and mechanical engineering, medical diagnosis and remote sensing, sound and heat control . Today, there is an urgent need for advanced studies exploring the engineering potential of such materials, and practical methods for their fabrication.

My research in this area aims at designing novel versions of pentamode materials: artificial structural crystals showing shear moduli markedly smaller than the bulk modulus. Novel systems will be designed to control the soft modes of these pentamode materials, through the tuning of the bending moduli of members and junctions, and/or the insertion of struts or prestressed cables within pentamode lattices.

Actuated pentamode metamaterials will be constructed and tested as seismic base-isolation devices, profiting from the low and adjustable shear moduli of such systems. In addition, pentamode materials will be experimentally used as components of new-generation seismic dampers

Physical models of such devices will be manufactured through novel additive manufacturing techniques (3D printing in polymeric and metallic materials). An experimental validation phase will investigate the mechanical response and the control of such models. It will lead to an evaluation of the scalability of the proposed solutions, and the associated economic benefits.

|

|

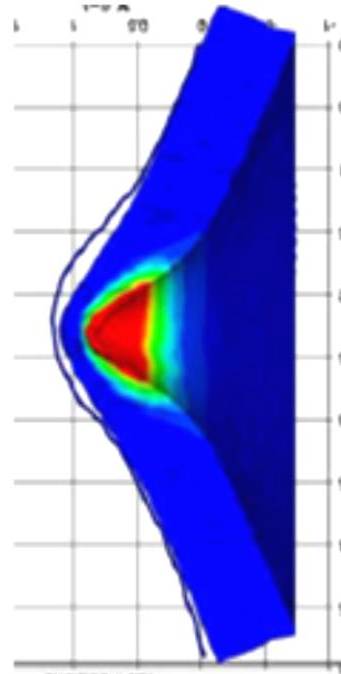

Use of pentamode lattices to design innovative seismic isolators:3D printed pentamode lattice confined berwwen stiffening plates (left);

dynamics of a pentamode isolator (right).

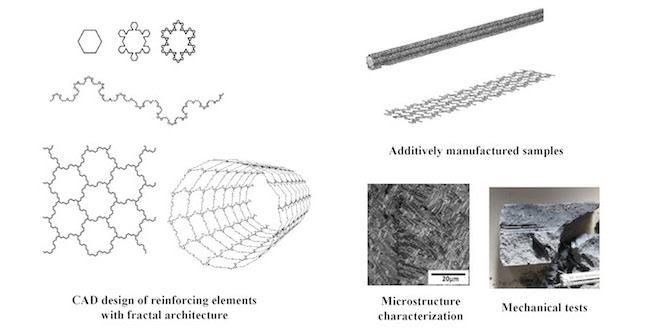

Reinforcing elements with hierarchical structure for the development of next-generation construction and building materials

The development of novel materials fabrication processes is attracting growing interest from scientists and engineers towards architected materials and structures. It is known that most natural materials exhibit hierarchical organization of matter and fractal geometries, which provide increased surface area for the same volume of material. Fractal geometry indeed permits the design of hierarchical patterns through self-similar subdivisions of basic shapes such as squares or triangles. This subdivision process can be repeated an infinite number of times, obtaining increasingly complex structures that exhibit fractal dimensions much greater than their topological dimensions. I have recently initiated a new area of research on the design, and microstructural and mechanical characterization of additively manufactured reinforcing elements for composite materials exhibiting fractal geometry, with a focus on the flexural reinforcement of cement-matrix composites. The examined elements are manufactured via an additive process, electron beam melting, from the Ti6Al4V titanium alloy, using a Koch curve construction ruled by different complexity parameters. Koch fibers and meshes havedesigned, additively manufactured and experimentally tested, through the use of the proposed fractal design procedure. The proposed design strategy of reinforcing fibers and meshes with fractal architecture shows promise as an effective tool to create mortar and concrete composites that feature enhanced bond strength and energy dissipation capacity, due to fractal interlocking phenomena and the development of rough fracture surfaces at the fiber-matrix interface. Such effects can be achieved at a custom-designed scale, depending on the nature of the matrix material and loading conditions, through the fine tuning of the complexity parameters that govern the fractal design algorithm.

Reinforcing bars and meshes with fractal architecture 3d printed in the titanium alloy Ti6Al4V

(paper, work in collaboration with the

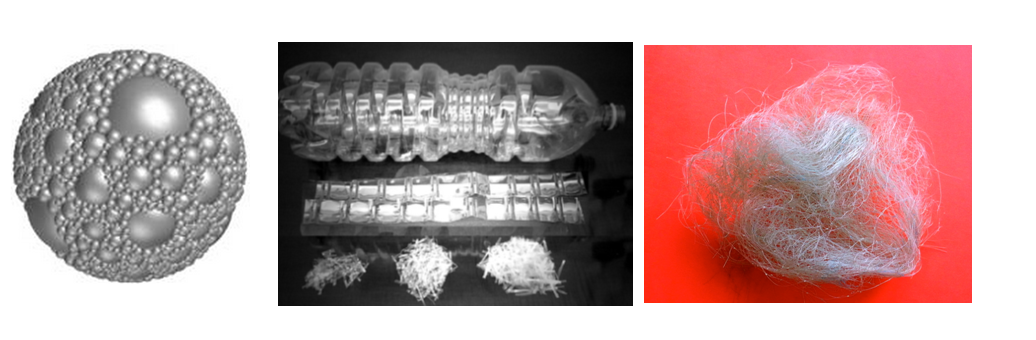

Left: Reinforcing particle with multiscale geometry (patent), Center: Cutting of R-PET reinforcing fibers from post-consumer bottles (paper), Right: Use of waste nylon fishing nets for mortar reinforcement (paper).

Four-point bending test on R-PET fiber-reinforced concrete (RPETFRC 1).

Multiscale modeling and simulation of materials and structures

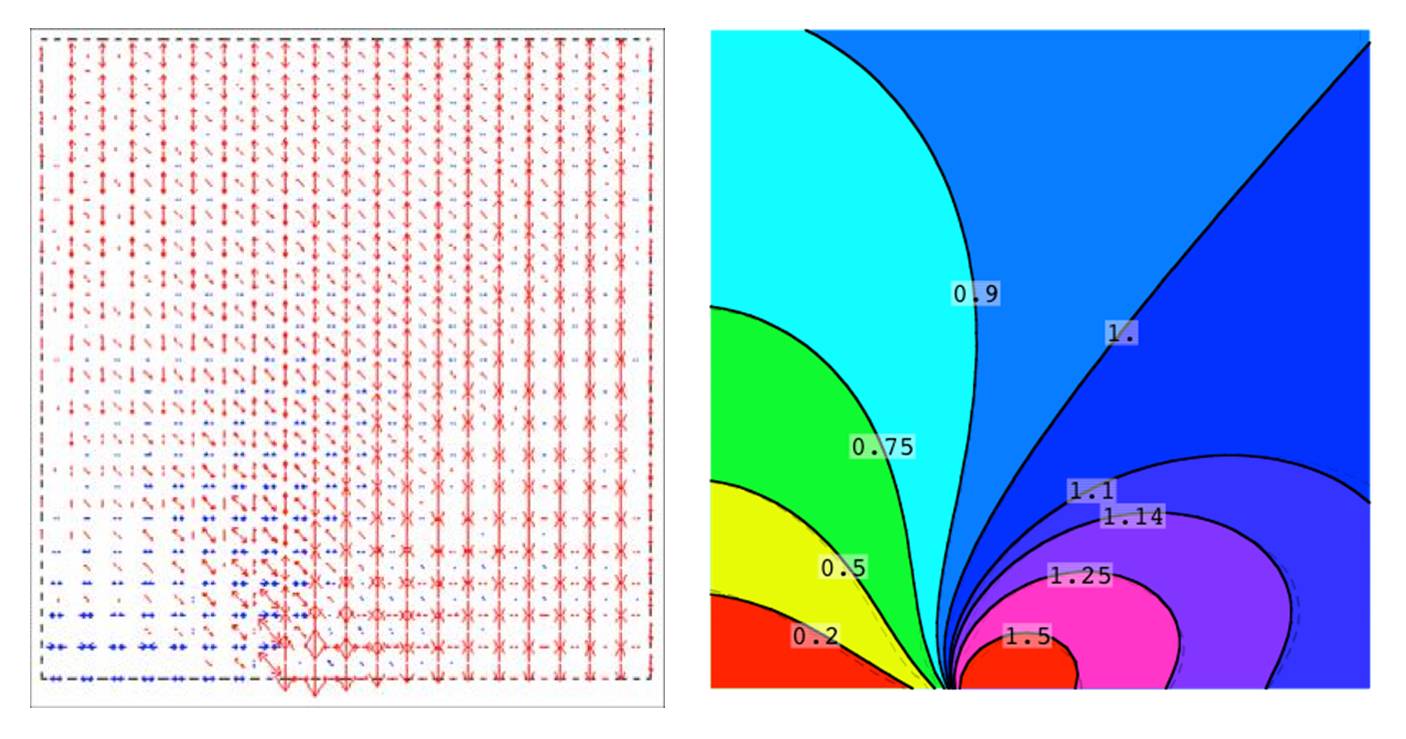

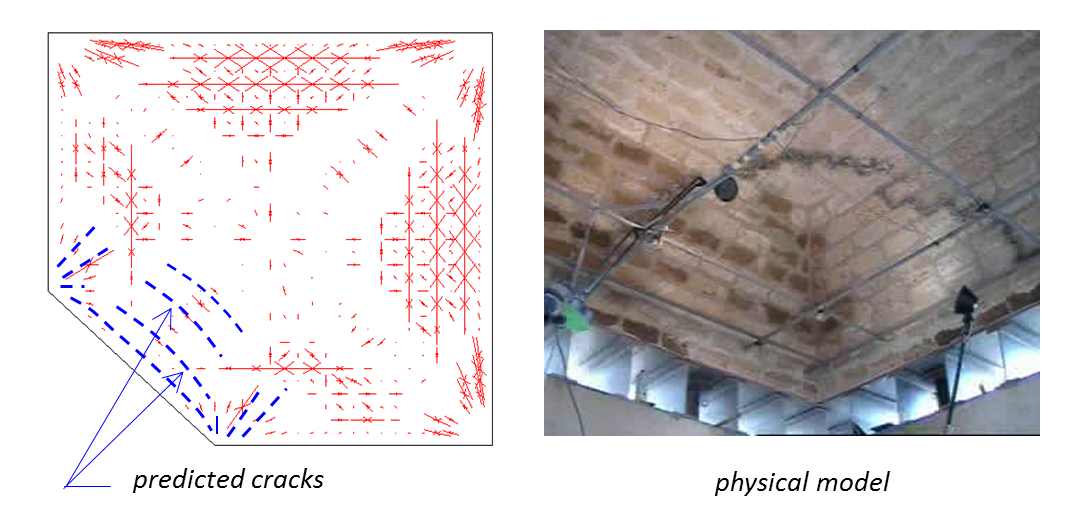

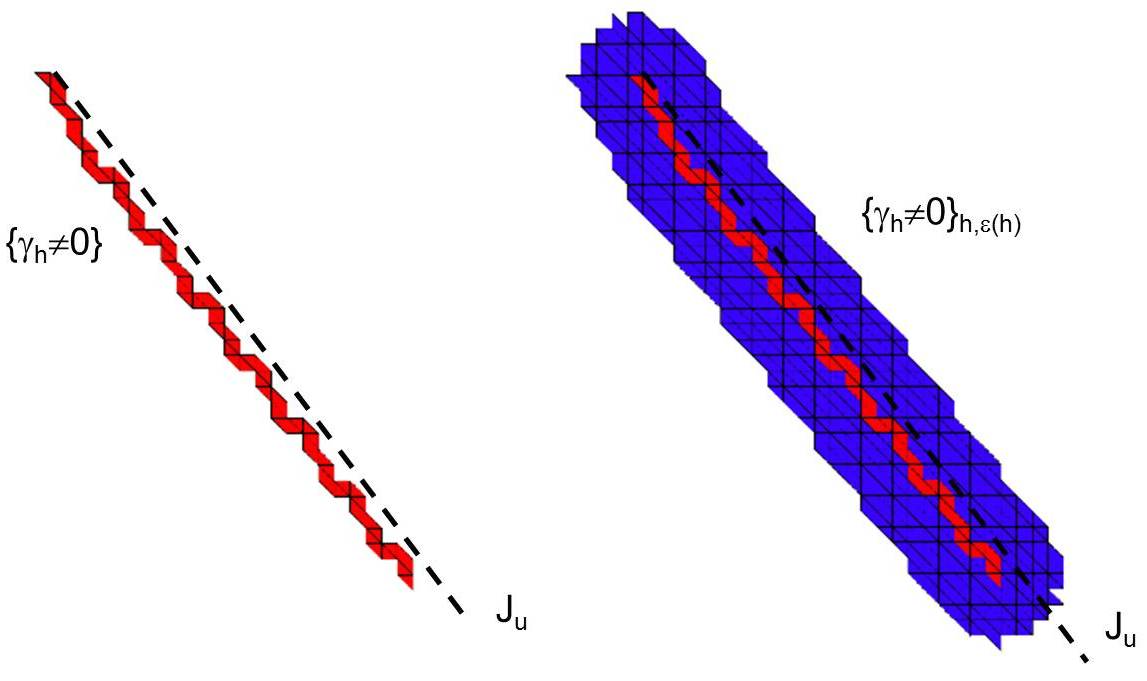

In recent years, I have worked on multiscale approaches to fracture and solid mechanics at the University of Salerno (Unisa, link), and the Graduate Aerospace Laboratories (GALCIT, link) of the California Institute of Technology (Caltech), within the Computational Mechanics Group directed by Michael Ortiz (link) and the Center for Advanced Computing Research (link). I have contributed to the formulation and numerical implementation of a variational method that represents a continuous body through an equivalent and unconventional truss structure (Lumped Stress Method or LSM, LSM 1, LSM 2, LSM 3, LSM 4). The LSM establishes a link between continuum and discrete mechanics, and considers the approximating truss structure as the support of singular (or lumped) stresses, which approximate the stress field of the background medium. I have also worked on multiscale approaches to fracture mechanics based on the reformulation of the classical Griffith energy criterion for brittle fracture within the mathematical framework of free discontinuity problems. Free discontinuity problems are those problems of calculus of variations where solutions can exhibit discontinuity points and their jump sets are a priori unknown. In fracture mechanics, the free discontinuities describe the crack path of the body. The latter and the displacement field are determined through minimization of a suitable energy functional, which is composed of competing bulk and surface terms. Energy minimization allows prediction of both nucleation and growth of cracks. A first computational approach that I have worked on employs finite element models incorporating discontinuous interface elements (strong discontinuity approach, FREE DISCONTINUITY 1, FREE DISCONTINUITY 2). In such models, the computation of the crack path turns into energy-driven mesh optimization. Optimal conditions apply, in general, to both the geometry and the topology of the mesh. A second approach approximates the energy functional with a family of functionals depending on a small parameter and two fields: the displacement field and an eigendeformation field that describes the fractures that occur in the body (weak discontinuity or smeared crack approach, EIGENFRACTURE). Specifically, the eigendeformations allow the displacement field to develop jumps that cost no local elastic energy. I have also worked on Local Maximum-Entropy (LME) approaches to membrane networks (MEMBRANES 1, MEMBRANES 2, MEMBRANES 3, MEMBRANES 4); and discrete-to-continuum models of carbon nanotube foams (CNT 1, CNT 2, CNT 3, CNT 4, CNT 5). Future work in this area includes the formulation of concurrent discrete-continuum approaches to the mechanical modeling of materials and structures across different length- and time-scales; mixed approaches combining the finite element method with discrete element methods; and discrete to continuum approaches to multiphysics simulations based on quansicontinuum methods and LME shape functions.

|

|

Eigenfracture approach to variational fracture: espilon-neighborhood technique to correct mesh dependency (left), and mixed mode I-II example (right) (paper).

Mechanical modelling of layered carbon nantotube structures

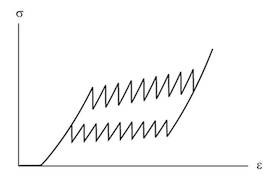

I have extensively studied the mechanical properties of dense, vertically aligned carbon nanotube (CNT) assemblies subject to compressive loading, starting with a mechanical model directly inspired by the micromechanical response reported experimentally for such structures. Infinitesimal portions of the tubes are represented by collections of bistable elastic springs. Under cyclic loading, the proposed model predicts switching between different elastic phases, hysteretic buckling, material densification, and fatigue damage. The continuum limit of the microscopic response leads to a mesoscopic dissipative element (micro-meso transition), which describes a finite portion of the structure. A series of mesoscopic units finally describes the macroscopic response of the CNT structure (CNT 1, CNT 3, CNT 5). In situ identification procedures have been proposed to quantify the material parameters corresponding to the microscopic (CNT 4) and mesoscopic scales (CNT 2). The mechanical modeling of CNT assemblies is a necessary first step toward the construction of lightweight multilayer CNT-based laminar composites with tailored collapse and energy-dispersive properties. Additional future work in this area will include the study of the acoustic response CNT structures and their use of novel acoustic metamaterials.

|

|

Left: Hysteretic response of a non-uniform chain of bistable springs

(CNT 5).

Right:

Multiscale modeling of layered structures based on carbon nanotube arrays (CNT 2).

Nonlinear dynamics of composite materials and structures

At GALCIT I have helped to construct a virtual shock facility for computing the mechanical response of a variety of target materials under dynamic loadings, including loadings produced by blast and ballistic events. This research program was hosted at the Center for Simulating the Dynamic Response of Materials, an ASCI/ASAP Center of Excellence at the California Institute of Technology. I have contributed to the development of a continuum framework including viscoelastic, elastic-plastic and cohesive models in finite strain kinematics for use in stress analysis, damage prediction, and fracture/ fragmentation simulation under dynamic loading of composite structures incorporating shock mitigation devices based on soft materials (IMPACT PAPER). Applications to be pursued comprise optimal design and assessment of a variety of structures under dynamic loading, such as polymer-steel sandwich plates; innovative protective helmets including honeycomb materials, polymers, or foam padding; virtual testing of motorbike helmets and other protective tools; multilayered coatings; structures under wave and flood slamming; seismic response of structures; optimization of crash and impact performance of materials and structures.

|

|

|

Left:

Simulation of a ballistic impact on a steel plate (with fragmentation).

Right:

Ballistic impact on a steel plate reinforced with a polyurea layer (no fragmentation, cf. IMPACT PAPER).

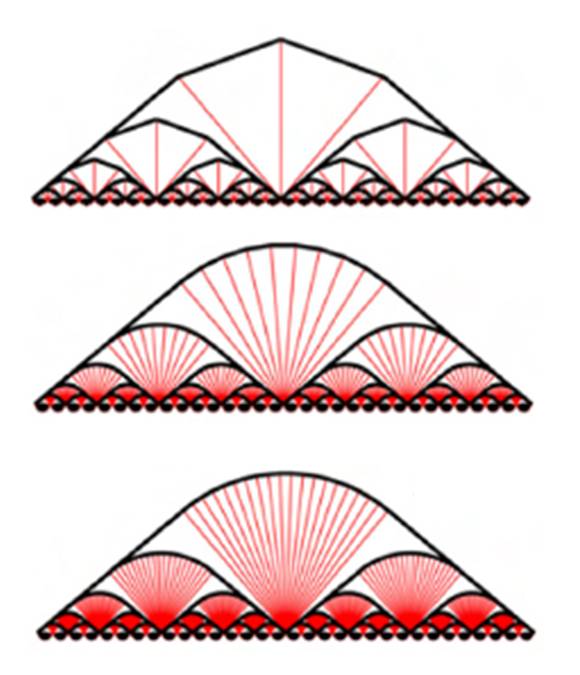

Form-finding problems and integrated structural optimization

I have investigated the form-finding of lumped stress models of no-tension structures (e.g., masonry structures, LSM 3, LSM 4); structural optimization techniques based on genetic algorithms and evolutionary strategies (GA optimization paper); and the parametric design of tensegrity structures (Tensegrity bridge paper 1, Tensegrity bridge paper 2). In the future, I plan to employ LSM to carry out studies on the form-finding and shape optimization of lightweight material structures. A first line of research will focus on the design of no-tension shapes of structural surfaces via polyhedral stress functions. Such strategies will allow the use of thin geometries for lightweight roof structures, domes, and vaults, including in the presence of limited material strength. A second research line will be the search for optimal truss network models of bridges, walls, or domes through mathematical programming techniques, evolutionary algorithms, and/or topology optimization strategies. The use of LSM models will lead to the parametric design and prototype fabrication of structural surfaces and vaulted structures. I will devote special attention to the optimal design of tensegrity structures incorporating steel, concrete, or wooden struts. The use of tensegrity architectures will lead to minimum mass shapes for single or multiple loading conditions. Optimization strategies based on self-similar subdivisions of basic modules will be employed, generating optimized tensegrity fractals with multiscale complexity.

|

Left: Tensgrity bridges with fractal architecture

(Tensegrity bridge paper).

Right:

GA optimization of a truss bridge (GA optimization paper).

MRC special issue

The special issue of Mechanics Research Communications (MRC) MULTI-SCALE MODELING AND CHARACTERIZATION OF INNOVATIVE MATERIALS AND STRUCTURES, Edited by Fernando Fraternali and Anthony D. Rosato, has been published into Volume 58 of MRC (Pages 1-156, June 2014) (www.multiscale.unisa.it/previous_edition).

JCOMB special issue

Fernando Fraternali, Luciano Feo and Robert E. Skelton announce that the special issue of Composites Part B: Engineering (JCOMB) titled COMPOSITE LATTICES AND MULTISCALE INNOVATIVE MATERIALS AND STRUCTURES, which is linked to the

Frontiers in Materials article collection

Fernando Fraternali, Chiara Daraio and Julian Rimoli announce that the research topic of Frontiers in Materials titled MULTISCALE LATTICES AND COMPOSITE MATERIALS: OPTIMAL DESIGN, MODELING AND CHARACTERIZATION, has been published.

MRC special issue

Fernando Fraternali and Glaucio Paulino announce that the special issue of Mechanics Research Communications titled ADVANCES IN MECHANICAL METAMATERIALS AND SMART STRUCTURES, has been launched (submission code: VSI:Mechanical Metamaterials).